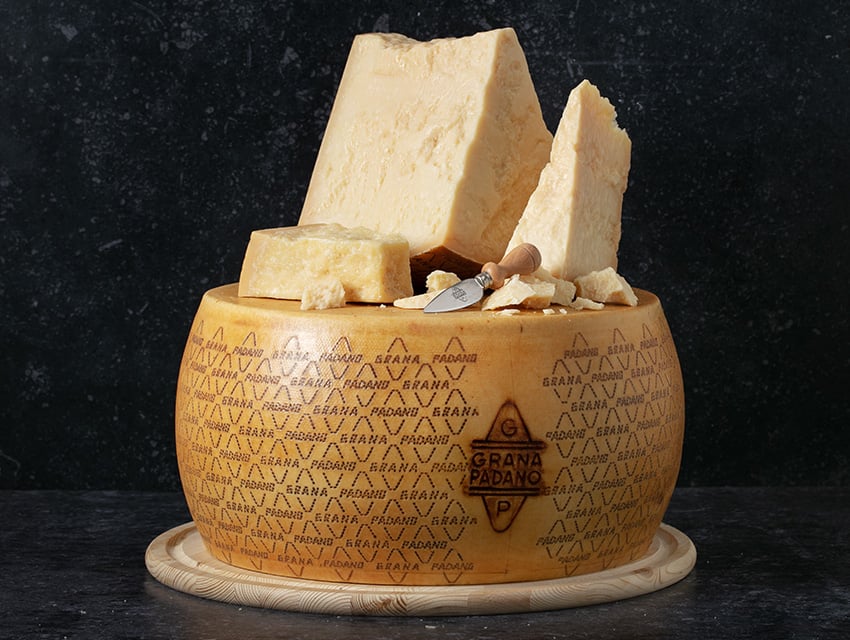

Grana Padano

PDO

No other type of dairy product can use the term “grana”, which is why the name of this Italian cheese should always be given in full: Grana Padano.

But when a food’s qualities set it apart, when it becomes known and loved across the world, and when the name – Grana Padano – is used by so many people, it becomes an example of excellence, a byword for a whole category of cheeses. Here at the Consortium, though, we believe in the importance of names, and we work to make sure they are respected. Because Grana Padano PDO is much more than a name: it is the story of an exceptional cheese, the story of centuries of tradition, passion and craftsmanship.

Ingredients

True excellence requires few ingredients. Rennet, lysozyme, salt and the highest quality milk combine to create something magical.

Ageing

The differing flavours of Grana Padano come from the ageing process. Different time periods, different ways to experience the wait.

How to Recognise it

Only the best wheels receive the fire brand, the official symbol that identifies Grana Padano PDO.

Nutrional

Education

Built on solid scientific foundations and involving a Scientific Committee, specialist doctors, dieticians and communications experts, this project aims to provide high quality educational materials to promote a lifestyle focusing on health and well-being.