Annie and Pad

Ciao kids!

I’m Annie, the Grana Padano cow.

I live in a cowshed near here, with my cow-friends.

We keep ourselves fit during the day with a bit of exercise, and we live on a healthy diet in order to produce the best milk.

We like a good feed, though, and just LOVE alfalfa! We are milked twice a day, and our milk is taken to the cheese factory.

Luckily, a super-expert in Grana Padano cheese works there… Pad the cheesemaker.

Every day, Pad pours the milk – after it has firstly been partially skimmed – into a giant kind of saucepan called a boiler and starts to heat it up.

While the milk is getting hotter, just like a chef following his recipe, Pad the cheesemaker adds the twomost important ingredients: the whey and the rennet.

Pad checks that the milk has coagulated perfectly and then, carefully breaks down the curd with a special giant whisk called “spino”.

In this way, the curd breaks into countless small granules.

Pad starts to boil the mixture and, having reached the correct temperature, he leaves it to rest so that all the little granules sink down to the bottom of the boiler to form a wonderful mass of delicious cheese.

The cheesemaker uses a long wooden pole to extract the mass of cheese that has formed at the bottom of the boiler.

Pad then divides it into two equal parts with the help of his friend, and wraps the two “twins” in linen cloths.

He then places them in moulds with a thick, heavy chopping board on top of each, to create the right shape.

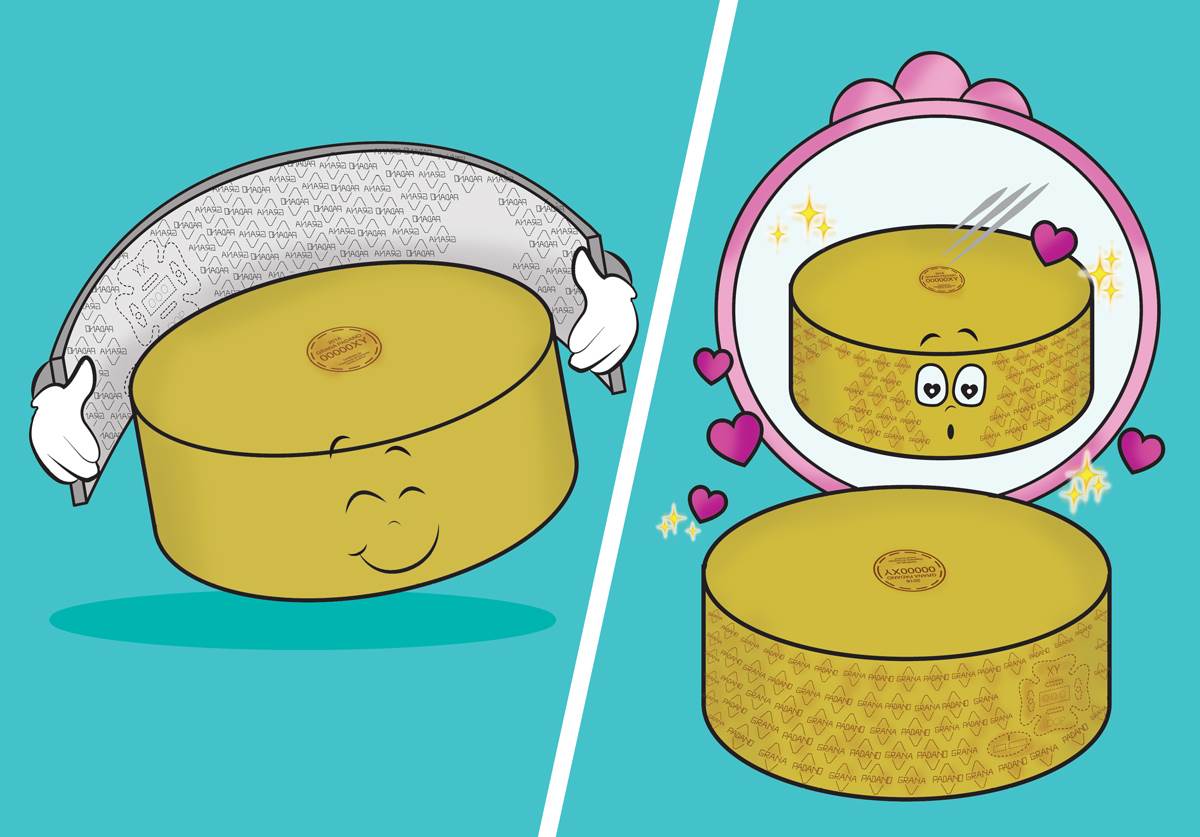

After a while, the big whole cheese is turned over and gets ready for some useful decoration.

Between the cheese and its mould, a belt is tied tightly, impressing its trademarks and origin stamps onto the Grana Padano wheel, making it a unique item, identifiable anywhere in the world.

Pad, meanwhile, has added a casein plaque on the flat top of the cheese.

Now we can clearly see each whole cheese’s origin marks, with its code name in two letters and numbers inside a four-leaf clover.

There we are! The cheese wheel is now ready for a long soak in a bath of salted water for roughly 20 days.

After its 20 day soak, Pad the cheese-man takes the cheese wheels out of the water and puts them in a warm place to dry, then they go to the ageing warehouse.

There are lots of other cheese wheels in this place: some are pretty young, and some are pretty old.

The period when all these cheeses sit neatly and quietly on the shelves in the ware-house is called the maturing phase.

After nine months of this ageing process, they are visited by an expert tester with a white coat and a case for his tools.

The expert places the cheese on a table and checks all the wheels: he uses a small hammer to test the cheese’s consistency, then inserts a needle to check its aroma.

Once it has passed all these phases and tests, the time has come for the finished cheese to be promoted!

It ascends the podium and proudly receives its fire-branding.