Ingredients

Grana Padano PDO cheese is produced with just a few, although exceptional, ingredients: milk, salt, rennet, lysozyme.

Grana Padano cheese is made from raw milk from cows which are mainly fed with fresh fodder, hay or silage. The milk is only sourced from the areas of production defined in the Production Specifications. The cows are milked twice a day or have free access to an automatic milking system, which respects the characteristics of the milk. The milk must then be partially skimmed by natural surface skimming at a temperature of between 8 and 20 °C. From the barn to the production line, it cannot undergo any physical, mechanical or thermal treatments that might modify its status of natural raw milk.

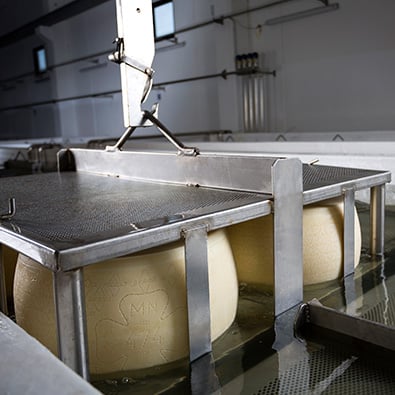

After spending at least 36 hours in moulds, the wheels of Grana Padano are immersed in a saline solution for the salting phase. The wheels remain in this solution for a minimum of 14 to a maximum of 30 days. The salt serves mainly to flavour the cheese, remove any leftover whey and form the rind.

Rennet enables the milk to curdle. As established by the Production Specifications, the rennet used in the production of Grana Padano is extracted from the calf’s stomach (abomasum). In the Grana Padano production process, a natural whey starter, made by fermenting the leftover whey from the previous day’s production process, is added before adding the rennet.

To control the effects of the development of unwanted fermentations due to the potential presence of spores of Clostridium tyrobutyricum in the milk, lysozyme is added to the milk before the rennet is added. Lysozyme is a protein naturally present in large quantities in human breast milk, tears and saliva. The lysozyme used in the Grana Padano production process is extracted from hen egg whites.

*N.B.: Lysozyme is not contained in all the types

of Grana Padano on the market, such as Trentingrana.

Lysozyme & Grana Padano PDO

Grana Padano PDO cheese is produced with milk from cows which have been fed on fresh forage, hay, corn silage or preserved fodder.

Grana Padano is produced with raw milk to which rennet, lysozyme and salt are added.

Silage is a traditional technique of fodder conservation typical of many areas of the Pianura Padana (Po River Valley) in Northern Italy, mainly used for whole maize/corn plants which are placed in special trenches where, following proper compression and air free conditions, natural acidification occurs. This fodder technique is part of the Grana Padano production traditions and enjoyed by cows.

In the preparation of preserved foods, hay or silage, a critical aspect is the possible contamination with soil that may contain bacteria such as Clostridium tyrobutirricum. If present in the silage, this bacterium can find favourable conditions for multiplying and passing in to the milk.

The milk produced for fresh milk, even of high quality, or to make soft cheese, comes from cows which are often fed with silage/preserved fodder, but clostridia need time to mature, so they haven’t got the time to develop in fresh milk or soft cheeses.

The milk for the production of Grana Padano PDO cheese is partially skimmed by natural surfacing of the cream and, during this process, most of clostridia are eliminated, but some of these microorganisms may remain in the milk and find the conditions to develop during the long ageing of the cheese and, after a period of time, abnormal fermentations may occur that compromise the cheese and its quality.

To control the negative effects of the Clostridium Tyrobutirricums’ development, lysozyme is added to the milk.

Lysozyme is a naturally occurring protein, extracted from egg white, and is also present in high quantity in breastmilk, in tears and human saliva.

Therefore, lysozyme is often used in the production of various aged cheeses, to control undesirable fermentations and its role is similar to that of a “fermentation process corrector”, inhibiting the development of clostridia.

Lysozyme is also used in the production of a few types of wine and beer.

Lysozyme is therefore a completely natural egg white protein, which is extracted with mechanical and not chemical methods.

The reason why it is completely safe to eat Grana Padano containing lysozyme:

– The quantity of lysozyme used is 25 g for 1000 litres of milk (265 US Gallons). Thus, the cheese absorbs a minimal, very low, quantity of lysozyme.

– Recent research into the alleged allergy possibility to the Grana Padano PDO lysozyme content, has shown that allergic reactions due to the presence of lysozyme in Grana Padano PDO are extremely rare in subjects with an egg allergy (20160211 DOC INFO allergenicity), although not excluded a priori.

Discover also:

Ageing

The differing flavours of Grana Padano come from the ageing process. Different time periods, different ways to experience the wait.

How to Recognise it

Only the best wheels receive the fire brand, the official symbol that identifies Grana Padano PDO.