Services

Quality Checks

For the Grana Padano Protection Consortium, quality is a fundamental value. For this reason, each wheel of cheese – before becoming Grana Padano PDO – is subjected to a meticulous evaluation process known as “espertizzazione”.

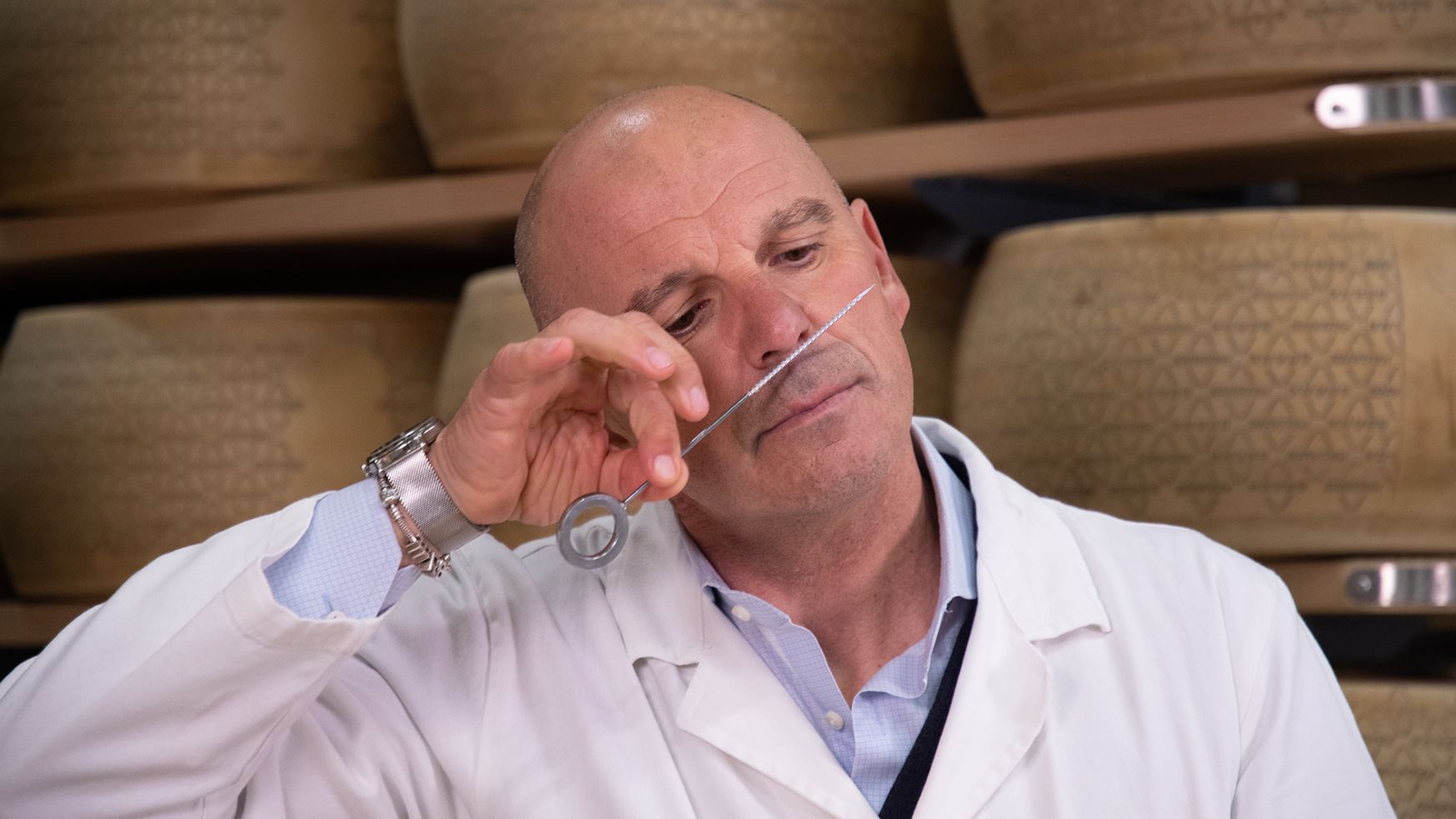

At the ninth month, the wheels are examined using the traditional test instruments – the small hammer, needle and probe.

Only the wheels that pass all the tests receive the fire-branded mark, certifying it is in compliance with all of the standards set forth in the Production Specifications that guarantee the “sound, genuine and marketable” quality of Grana Padano PDO.

The dairy production technicians apply the fire-branded mark under the watchful eye of the officials of the Protection Consortium, with the approval of the certifying body (CSQA).

Without this brand, the cheese cannot be named or sold as Grana Padano PDO.

While this is a very tough and burdensome process, it offers important benefits for the consumer in terms of quality and food safety. As we will see, this process is performed on the most valuable wheels of Grana Padano PDO, which are subjected to the longest maturing processes.

Temperature and humidity control in the warehouse: The experts carry out the first check upon entering the maturing warehouse, where they ensure the temperature is between 15° and 22° C and the humidity is between 80 and 90 per cent.

The experts carefully observe the wheels to ensure all the required distinguishing marks are present:

Each one must bear the following marks:

– the Quadrifoglio, or four-leaf clover, in which the serial number indicating the province, month and year of production must be stamped;

– the diamond-shaped lozenges, all around the side, with the words “Grana Padano”

– the CE mark, certifying the conformity of the product with EU health standards, present under the four-leaf clover

The flat surface of the wheel must also bear the casein plate which will then become part of the rind, bearing a code that identifies the wheel, ensuring its traceability.

The visual check also verifies the absence of faults, such as lumps, spots, tears, or mould.

Tapping is the first important check that certifies the conformity of the wheel to the Grana Padano PDO Production Specifications and therefore its eligibility for fire-branding.

It is considered an important ritual and involves the use of high precision tools: the small hammer, a sharp ear and the extensive training of expert hammerers.

“The process requires experience and skill, and can detect irregular lumps or cracks caused by abnormal fermentation. To ensure the wheel is compact and even inside, the technicians test to see if the sound is constant and even on every sideof the wheel, when tapped with the hammer.

The small hammer is the tool used to tap the cheese. It is made of a metal alloy (lead and iron).

After the visual check and the tapping test, the technicians can proceed with the next step, which involves the use of the needle.

The needle is a screw-shaped tool that enables the technician to penetrate the wheel for a few centimetres, and collect a small sample of product.

This sample is then examined to check the colour and aroma of the cheese.

To be absolutely certain that each wheel of cheese is of the highest quality, a special probe is used to extract a small sample, about 1cm in diameter and 7-8 cm long to be exact.

This way, the fragrance, colour, and texture of the paste can be assessed and any faults or defects can be detected.

The wheels of cheese that do not meet the Product Specification requirements are “etched”.

This is performed using an “etching machine”: a particular tool, exclusively owned by the Protection Consortium, which enables all the distinguishing marks of Grana Padano to be covered in crossed out and so removed. The casein plate and CE mark are also removed.

The etched cheese wheel can be sold as “Italian hard cheese”.

Once all the quality checks have been completed, the experts of the Consortium issue a detailed report stating, in particular: quantity of wheels tested, quantity of wheels fire-branded, number of etched wheels, if any, percentage of selected cheese, and average weight of the lot.

The test report is precise. The number of discarded wheels reported must correspond exactly with the number of wheels subsequently etched.

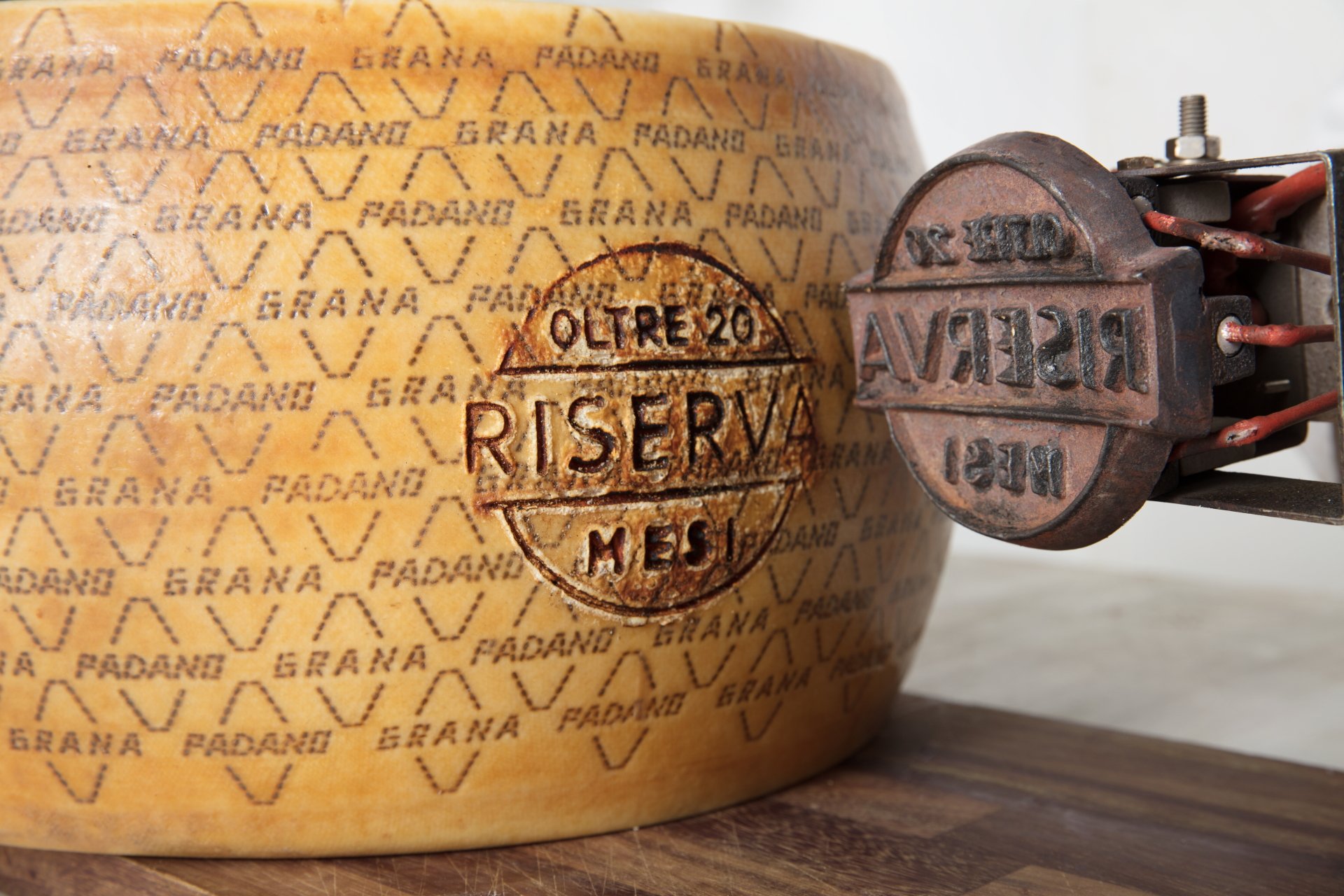

The experts then check the wheels to that they applied the “Grana Padano” fire-branded marking after the 9-month maturing process, carrying out another in-depth test to certify the cheese as “Riserva – Oltre 20 mesi” (Reserve – Over 20 months).

In this case the checks are even stricter: According to the Production Specifications, the wheel must be “scelta sperlata”, which means that it must be considered free from defects, a status verified by further tapping and visual checks.

The tapping performed to determine a wheel’s Riserva status is extremely meticulous: In this case, the wheels provide a different response to a different sound. In particular, the sound is constant, consistent and sharper than in wheels subject to a shorter maturing processes. This cheese produces different sounds due to its texture which, during the extended ageing process, loses humidity and gradually becomes drier.

The colour of the cheese is the same throughout the wheel: it goes from a straw yellow to a more amber shade (the variation in colour can depend on the type of warehouse, the humidity and the way the wheels are turned).