Grana Padano

fun facts

Discovering the secrets behind Grana Padano means taking a trip through the fun facts about the world’s most popular PDO cheese.

How it is born, the production process, the various forms, cutting the wheel: the world of Grana Padano is extensive, fascinating, generous… and just waiting to be explored.

The world of Grana Padano

How to cut Grana Padano wheels

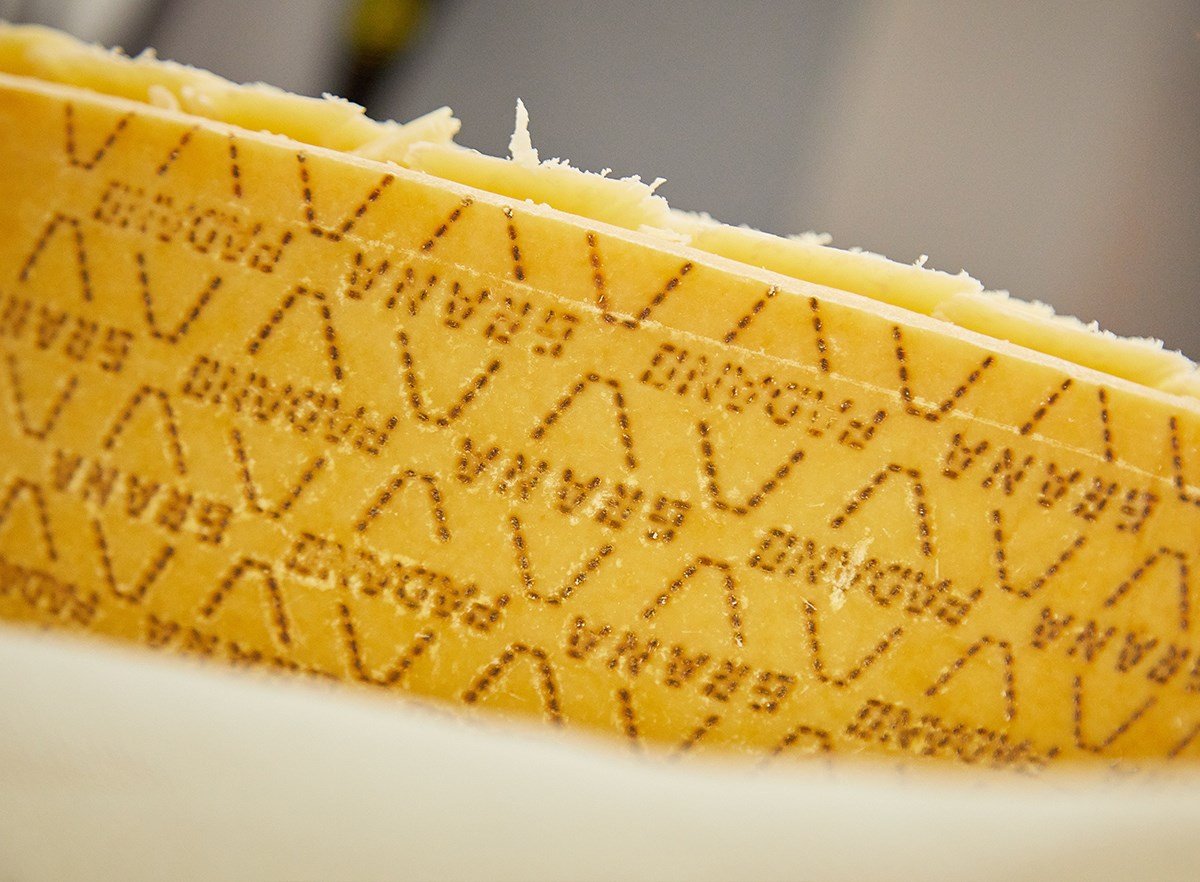

Opening a wheel is like a ritual, a process to be carried out with precision and care. The full wheel is cut with geometric precision using careful movements honed over time and perfected by the best master cheesemakers.

This creates the perfect “wedges”, and the ideal balance between cheese and rind, to guarantee a flavour that is a true triumph of sensations.

Grana Padano and Parmigiano Reggiano – Particular aspects and specifications

Many people also know that both these cheese are classified as “Denominazione di Origine Protetta”, i.e. Protected Designation of Origin, and also know what this means in terms of product characteristics compared with similar but generic products.

Is the rind of Grana Padano edible?

Technical-scientific notes on the food safety of the Grana Padano PDO cheese rind

Grana Padano PDO is a safe food, as specific testing has shown that the production process set in the Production Specification Rules guarantees the elimination of any pathogens potentially present in the raw milk used, which might subsequently develop in the cheese. This occurs as a result of the combined effect of the temperature and pH established during the production process of the wheel, thanks to natural lactic fermentation, which continues for several hours.

The outermost part of the cheese gradually becomes rind. It first begins to form around 24 hours after production, completing its development thanks first to the salting of the cheese in brine and then to the subsequent maturing process, which must last a minimum of 9 months. During this time, the rind hardens to protect the cheese inside.

The wheels are left to mature in dedicated warehouses with controlled temperature and humidity. Over the long months of maturing, the wheels are regularly brushed, cleaned and turned; this not only favours the loss of humidity but also eliminates any surface contamination by moulds present in the environment, which could form on the surface as a result of natural exudation.

Hence, during the maturing phase, the Grana Padano PDO rind acts as a barrier against any external agents which could compromise the cheese.

Once the cheese obtains the Grana Padano PDO fire-brand, it can be sold subsequent to cleaning and, in some cases, transformed into portions, grated cheese, chunks, flakes or other processed products.

The Grana Padano PDO rind is therefore an integral part of the cheese and is perfectly edible once the outermost surface has been carefully cleaned, as with the peel of an apple, for example; indeed, in accordance with the Production Specification Rules, the rind does not undergo any chemical treatments and is not covered by any colouring or plastic material.

As for all non-pre-packaged foods, all those who come into contact with the product at any stage of the sales chain are obliged to implement a HACCP system, in compliance with food industry requirements.

Proper application of the HACCP system ensures the food safety and edibility of the rind of Grana Padano PDO cheese.

The use of the rind of this cheese as a food product is therefore correct, permitted and indeed included among the ingredients in a number of recipes.

Bibliographical references

L. Pellegrino et al (2001), CHEESEMAKING CONDITIONS AND COMPOSITIVE CHARACTERISTICS SUPPORTING THE SAFETY OF THE RAW MILK CHEESE ITALIAN GRANA, Sci. Tecn. Latt. Cas., 52 (2), 105-114

VALUTAZIONE DELLA SICUREZZA MICROBIOLOGICA DI FORMAGGIO GRANA PADANO DOP – documentazione a cura dell’Istituto Zooprofilattico Sperimentale della Lombardia e dell’Emilia Romagna.